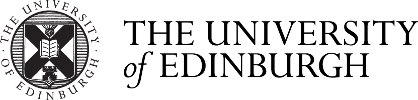

The two pistons allow the independent control of the pressure and flow velocity profile in the DP-PSA system. This can be used to test a wide range of pressure swing configurations. The images show an example with:

- Piston 1 starting the cycle at the minimum stroke and moving towards the column

- Piston 2 starts halfway between minimum and maximum stroke and moving away from the column

- The stroke length of piston 1 is 1.5 times that of piston 2

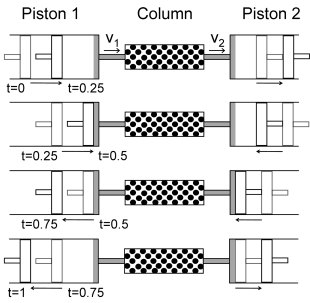

The pressure and velocity profile show the operation of a binary separation:

- At high pressure the flow is mainly negative

- The heavy component adsorbs while the light component moves in the negative direction

- At low pressure the flow is mainly positive

- Both components move in the positive direction

- Resulting in the separation of the two components

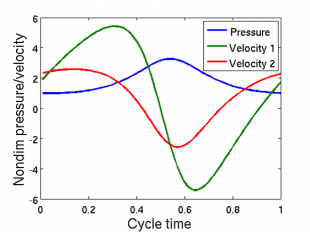

The simulation was performed with the in-house general adsorption cycle simulator CySim.